Our Solution

The J&JECTORS team has developed a desktop insert molding machine for rapid medical device prototyping. Designed for R&D engineers, this compact unit brings professional-grade injection molding to the workspace—with no outsourcing required.

Key Features

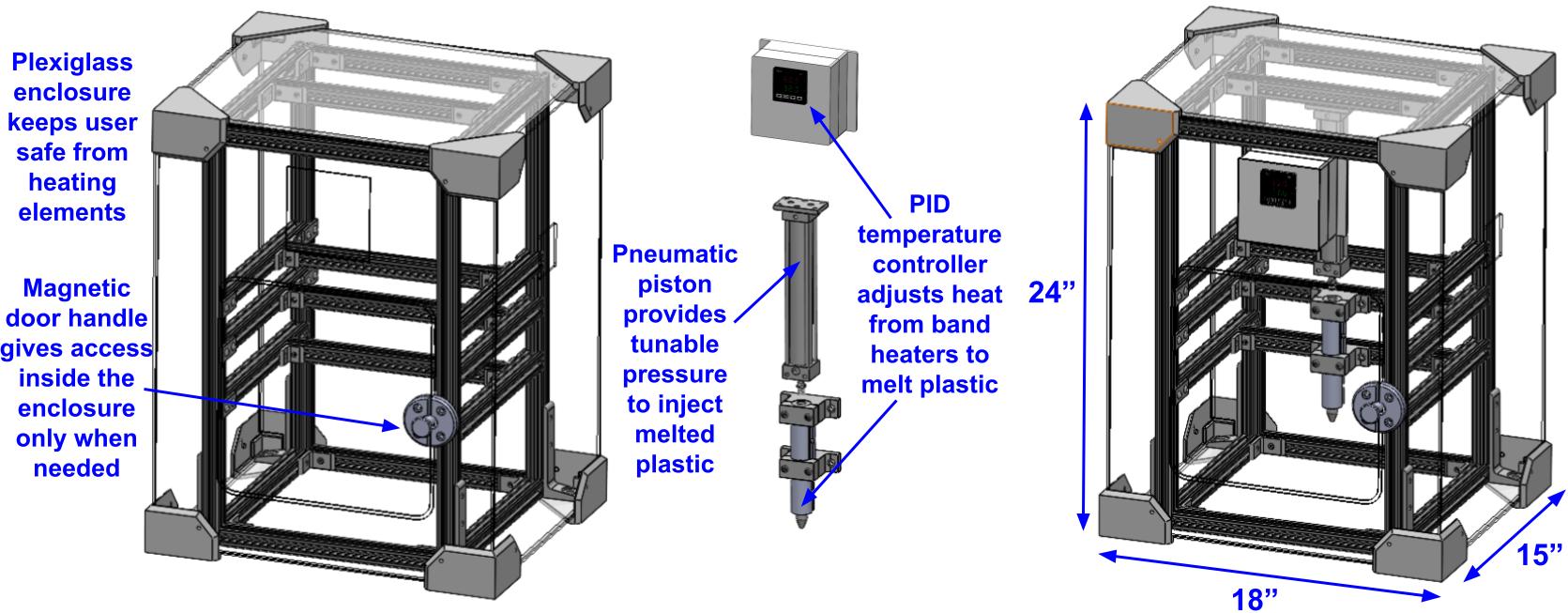

- High Precision Molding: This device is engineered to achieve the precise temperature and pressure parameters necessary for molding high-performance thermoplastics. Featuring a robust PID heat controller and pneumatic system, it ensures consistent material flow and accurate replication of mold details, essential for applications requiring tight tolerances and superior surface finishes. Ideal for both prototyping and functional testing, the system supports the production of components that demand strength, durability, and complex geometries.

- Compact Footprint & Quiet: Designed with space efficiency in mind, the device features a compact form factor that fits comfortably on a standard workbench or laboratory table. Its small size makes it an excellent choice for research labs, startup environments, or in-office product development spaces where space is limited but high-functioning tools are essential. Despite its compactness, it delivers the power and capability typically associated with larger industrial machines, while maintaining a low volume.

- Versatile Compatibility: The molding system is compatible with a wide array of thermoplastic materials commonly used in medical device R&D. This versatility allows users to test and prototype using the same materials intended for full-scale production, enabling more accurate performance evaluations and reducing the need for costly reformulation later in the development process.

- Quick Mold Swapping: Designed for speed and flexibility, the system enables rapid exchange of molds, significantly reducing downtime between iterations. This feature is especially beneficial for fast-paced prototyping environments where time-to-market is critical.

- Designed with User Safety: User safety is a top priority in the design of this molding system. The entire unit is enclosed to protect operators from direct exposure to heated components and moving parts. It adheres to Environmental Health and Safety (EH&S) standards, incorporating features such as an enclosure to protect operators from touching heated parts, allowing safety to both professionals and new trainees.