Our Solution

Learn about how J&JECTORS injection molder works.

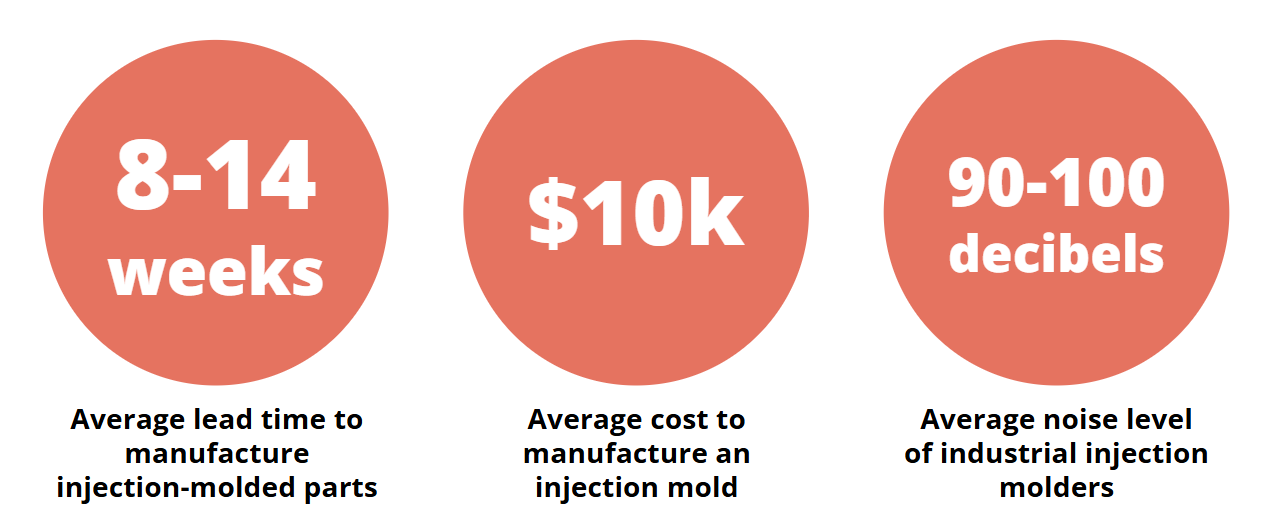

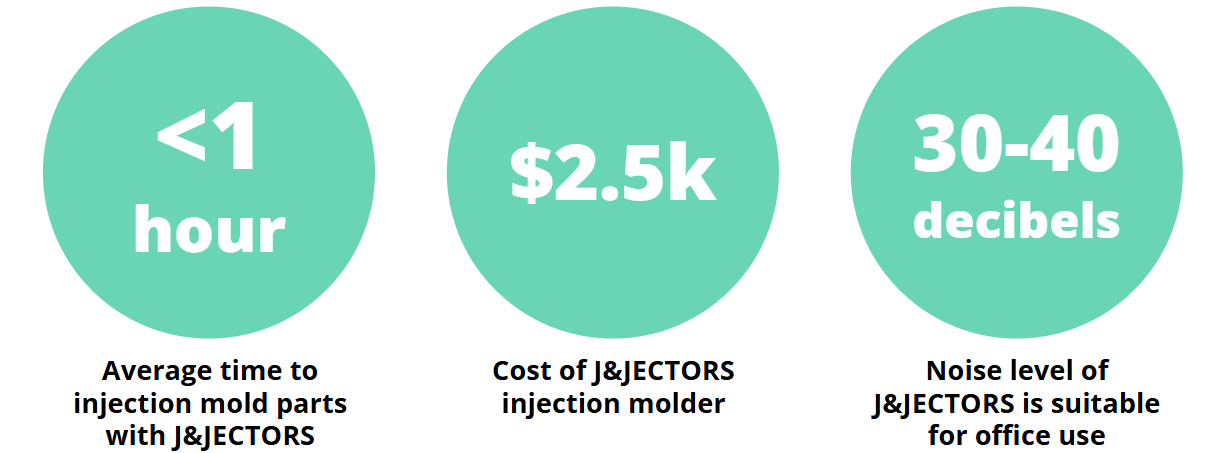

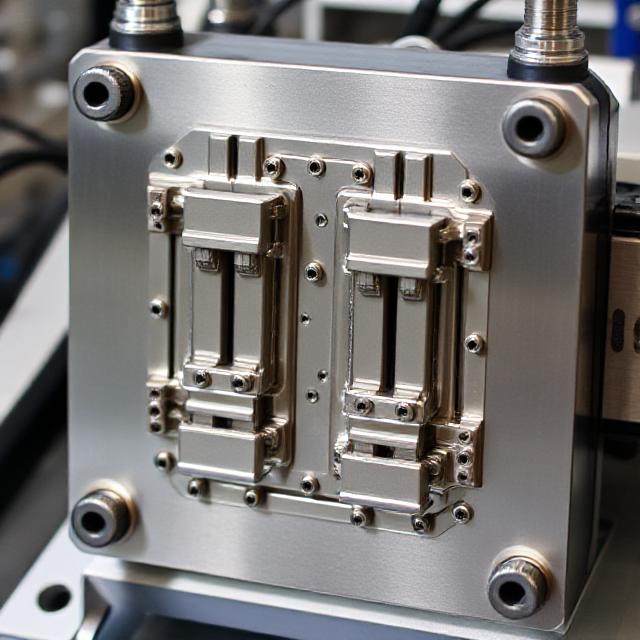

Imagine trying to develop a life-saving medical device, but every time you want to test a small change, you have to wait weeks — and spend thousands of dollars — just to get a new prototype. In medical device development, we’re racing against the clock — trying to iterate quickly, test designs, and move technologies forward. But right now, if you need a new injection-molded part, you have to wait on external vendors to manufacture it for you. That means most engineers resort to glued, 3D-printed stand-ins that can fall apart — sometimes literally — during pre-clinical trials in front of physicians. It’s not just embarrassing; it slows innovation and undermines confidence. For current injection molders... We’re designing a compact, EH&S compliant, and budget friendly injection molding system that brings rapid prototyping into the lab — so engineers don’t have to wait months or spend tens of thousands just to test a change. With our device...

Learn about how J&JECTORS injection molder works.

Read more about how J&JECTORS plans to fill in the market gap.

Get more info about the people behind the project.